DUKELARRSEN Grooved Coupling & Grooved Fitting

ส่งฟรี กรุงเทพมหานคร ปริมณฑล ชลบุรี ระยอง สามารถสอบถามได้ที่ช่อง Chat หรือโทรหา ติดต่อสอบถามส่วนลด ราคาเพิ่มเติม ติดต่อ Dealplustech ได้ตลอดเวลาทำการ

Telephone : 090-555-1415

E-mail : dealplustech@gmail.com

Line Id : Jppselection

4 เหตุผลที่ควรใช้ระบบกรู๊ฟ

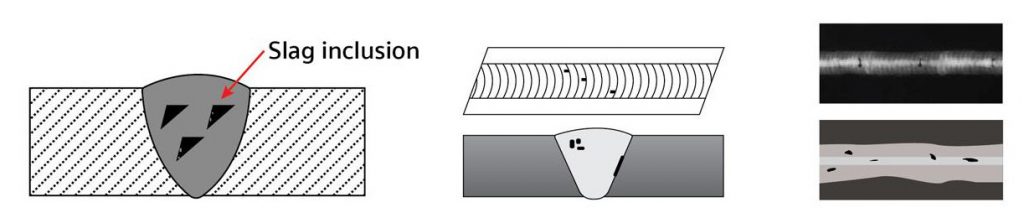

1. ไม่เกิดการอุดตันจาก Slag (เศษผงเหล็ก)

2. รูพรุนจากรอยเชื่อม ต้นเหตุของการเกิดท่อผุ รั่ว ซึม ในที่สุด

3. การเชื่อมแบบดั้งเดิมอาจก่อให้เกิดเศษผงเหล็ก (Slag) ฝังในรอยเชื่อมที่อาจส่งผลให้เกิดท่อผุ รั่ว ซึมในที่สุด

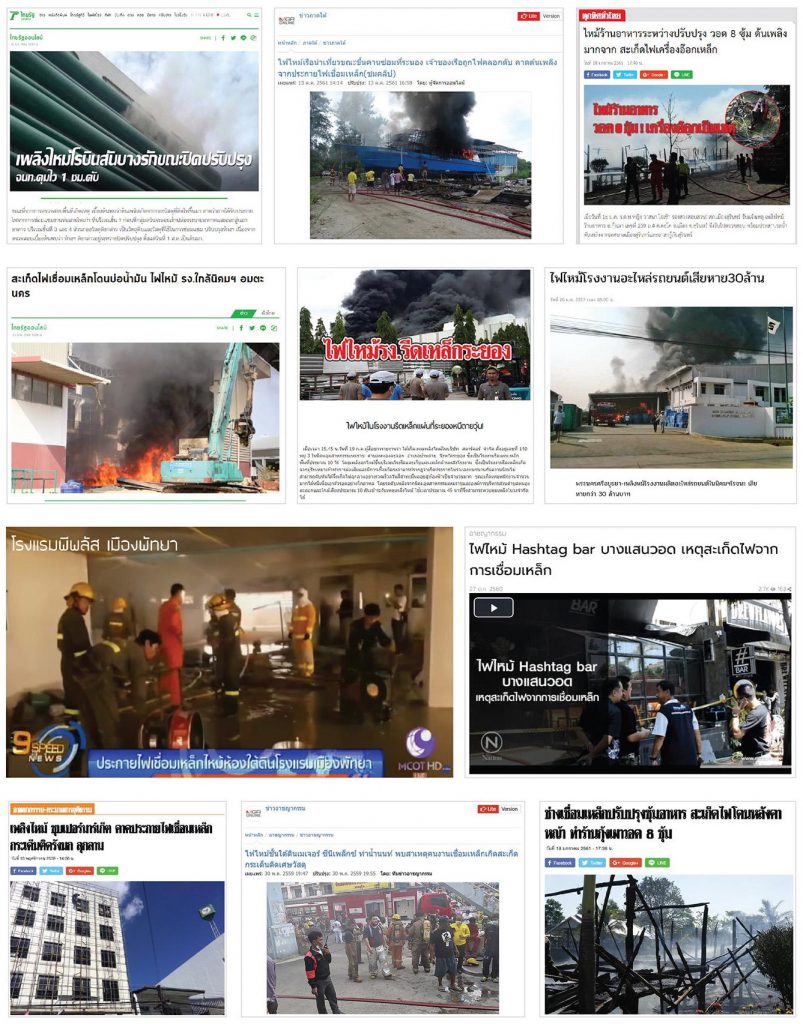

4. การเกิดประกายไฟ

GROOVED COUPLINGS AND FITTINGS

1. Reduce installation costs

- easy to assemble, no special training required

- minimal equipments are required

- fast assembly in tight places

- free of welding, no pollution

- lower installation costs

2. Flexibility and rigidity

- The flexible coupling allow expansion, contraction and deflection because of the

changing temperature - The rigid coupling can provide the connection as well as welding

3. Joint reliability

- The couplings engage the pipe around the fill circumference and restrain the pipe

ends from separation due to pressure and other forces, up to the maximum coupling

rated working pressure.

4. Isolate noise and vibration

- Pre-designed slight gap between pipe ends and elastomeric gasket help to isolate

and absorb noise and vibration.

5. Convenient joint

- Coupling can be disassembled easily permitting removal of pipe section for cleaning

or servicing. It will facilitate periodic rotation of pipe to distribute internal wear from

slurries or other abrasive media

Coupling

Rigid Coupling DUKELARRSEN

Flexible Coupling DUKELARRSEN

Reducing Flexible Coupling DUKELARRSEN

Fitting

หน้าจาน PN16 Grooved DUKELARRSEN

หน้าจาน ANSI 150 Grooved DUKELARRSEN

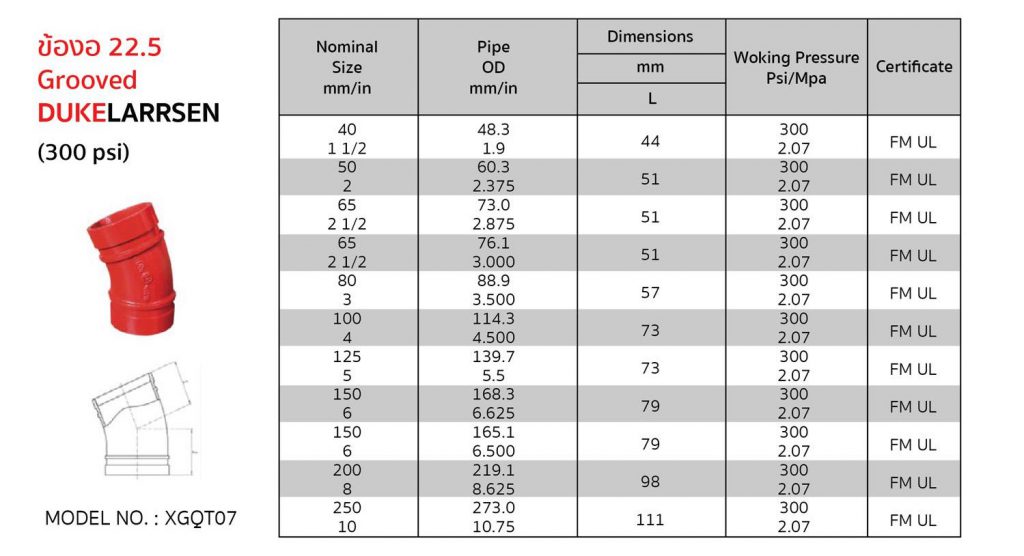

ข้องอ 22.5 Grooved DUKELARRSEN

ข้องอ 45 Grooved DUKELARRSEN

ข้องอ 90 Grooved DUKELARRSEN

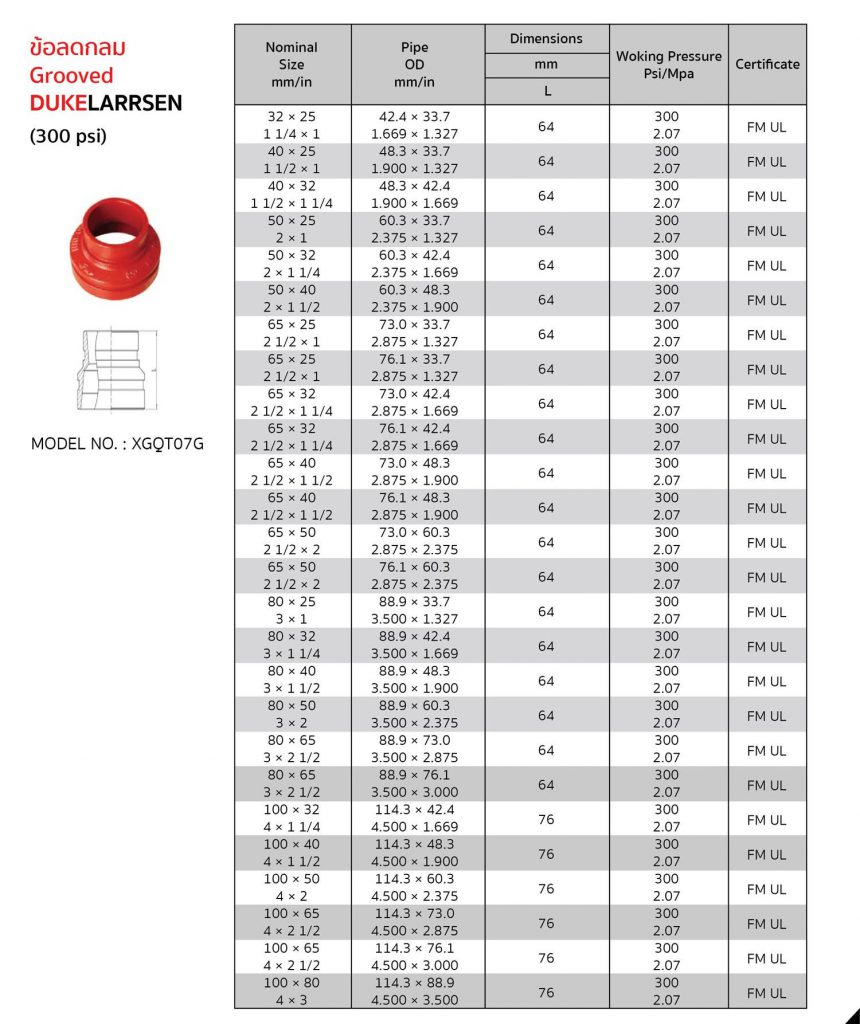

ข้อลดกลม Grooved DUKELARRSEN

ข้อลดเบี้ยว Grooved DUKELARRSEN

สามทาง Grooved DUKELARRSEN

สามทางลด Grooved DUKELARRSEN

สามทางลดเกลียวใน Grooved DUKELARRSEN

สามทางลดเกลียวใน Threaded Grooved DUKELARRSEN

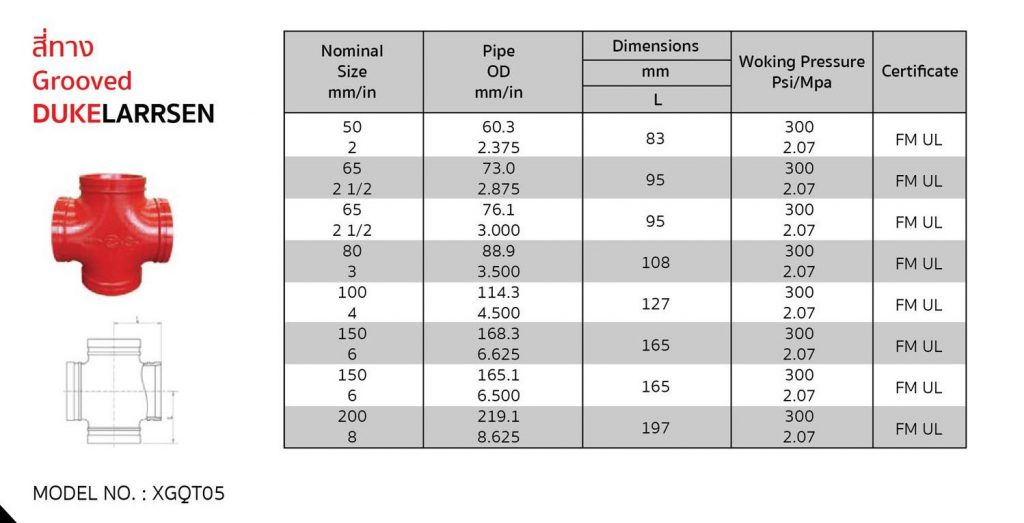

สี่ทาง Grooved DUKELARRSEN

สี่ทางลด Grooved DUKELARRSEN

ฝาครอบ DUKELARRSEN

Cap with Eccentric Hole DUKELARRSEN

Coupling

รัดแยกสามทาง Grooved DUKELARRSEN

รัดแยกสามทางเกลียวใน Threaded Grooved DUKELARRSEN

รัดแยกสาม U-Bolt Grooved DUKELARRSEN

Casting

As for the chemical composition, we do test and analysis every batch of the casting parts to ensure the chemical components meet the design requirements. For every package of the molten iron, there is a tensile test specimen in the lab, we check it one by one. So we can ensure that the casting always meet the requirements, and ensure every coupling and fitting are safe enough when it works under the rated working pressure.

BOLTS AND NUTS

As for the bolts and nuts, we choose 40 Cr as its material. Mechanical property of the bolts and nuts can reach to grade 8.8 after heat treatment. We can only use one wrench to install them, and the bolts and nuts are much better in reliability and fastness.

BOLTS AND NUTS

Quality Control

The certified product depended on the advanced scientific production equipment.Our casting production use casting air of wet-type clay so as to guarantee the need of volume production..Our casting production selects advanced processing system of complete regenerative clay,which adopts PLC integrating control so that the quality of clay mixed is stable and reliable‘We use two diffenert kinds of casting sand to enhance the surface smoothness.The modeling applies the air microseism compaction modeling line and two -sided template with escaping boxmodeling line,the size precision and the size stability of the product both are great.The iron smelting uses the domestic advanced intermediate frequency inductive oven and carried on test and adjustment by the direct-reading spectrometer an the quality controller of molten iron to avoid the entering of the harmful impurity

CASTING SAND TEST

Casting sand is one of the most important factor of enhancing the surface smoothness of the products.Our company introduced advanced casting sand analysis equipment, in the light of the property of the casting sand such as the pressure to sands, moisture content, gas permeability, mud content, wet-thermal tensile strength,theargil, thebudgust,and the blue absorption power, processing a strict analysis testing to enhance the quality of casting sand, so as to improve the fineness and the qualified rate of the products. Really attach importance to the details of the product’s quality.

METALLOGRAPHIC TEST

Metallographic test mainly processing the tests to the component of the casting part, to ensure the mechanical properties of the products. The testing adopt 500-600 times optical microscope to process the testing of molten iron’s nodularization rate, to ensure the nodularization rate of every cast of the molten iron to be above the grade 3. This testing is one of the important part of production process to guarantee the quality.

CHEMICAL COMPONENT TEST

There are complete equipments in the Chemical Laboratory, such as molten iron analysis equipment, carbon and silicon analysis equipment, spectrophotometer, etc. They are used to process the fast and accurate tests to the main components including carbon, silicon, manganese, sulfur, phosphorus and the microelements such as tombarthite and magnesium in the raw materials and finished products, to ensure the scientific proportioning of the raw materials. At the same time proceeding the online control of the components in the production process, to ensure every process of the production meets the requirements by applying the scientific composition ratio.

MECHANICAL PROPERTY TEST

Mechanical property testing laboratory introduced Computerized Electro-hydraulic Servo Universal Testing Machine to proceed the whole series of stretching, compressing, bending tests for the materials such as bolts and nuts which are required to reach the mechanical property performance index. By testing, the torque of bolts reach to grade 8.8, nuts reach to grade 8. All the casting products of our foundry reach the criteria of OT450-10,The hardness of our cast fittings, bolts and nuts are reach criterias of FM1920, UL213 by Blovi hardness testing.

GASKET RING SEALING TEST

The gasket ring is the important part of grooved joint fittings. The quality of gasket ring directly related to the quality guarantee period of construction projects. All the gasket rings of our products are produced by subsidiary factory, so that to ensure the scientific formula and optimization of production process. At the same time, every batch of the gasket rings are proceeded to strictly property test, including hardness, strength, stretching rate, aging in hot air, oil resistance, etc. The tests prove that every batch of the gasket rings meet the criteria of FM1920, UL213, and guarantee a long time usage period.

GROOVED JOINT FITTING PROPERTY TEST

Grooved joint fitting property jaboratory meet the requirement and criteriaof FM,UL. Including hydrostaticpressure test, compression strength, withstanding sealing performance, bending moment, torque, vibration, low-temperature resistance, refractory property, etc. The evaluation and routine tests for the new products, and the product performance tests are all conducted in this laboratory. And every batch of grooved joint fittings are all proceeded the destructive test, to ensure meet the criteria of FM1920, UL213